ITOCHU Announces the Cooperative Development of Material Recycling Technology for Multi-layer Film Packaging

December 16, 2020

ITOCHU Corporation (headquartered in Minato-ku, Tokyo; Yoshihisa Suzuki, President & COO; hereinafter “ITOCHU”) announced today that it has entered into an agreement for cooperative development of material recycling technology (*1) (“the technology”) for multi-layer film packaging with Toyo Ink SC Holdings Co., Ltd. (headquartered in Chuo-ku, Tokyo; Satoru Takashima, President & COO; hereinafter “Toyo Ink Group”). They aim to make the world’s first (*2) high quality material recycling practical by 2022, utilizing the technologies and networks of both companies.

Recently, trends related to the problem of disposable plastic have attracted attention globally, and responses are being hurried. In Japan, while about 16% of plastic that is eliminated as waste is simply burned, buried, or otherwise processed without being reused, about 56% relies on incineration methods, such as the thermal recycle and heat reclaiming. Currently, large amounts of plastic are not recycled. In particular, food packaging, refill pouches for detergent and other sanitary products, and film packaging, known as flexible packaging, feature a multi-layer structure that uses many materials to ensure the required performance, which differs based on use. This includes printed ink and adhesives between the polyolefin or polyester film. A major problem in recycling these materials is the difficulty in separating the layers.

Last year, Toyo Ink Group developed a technology to separate the ink, adhesive, etc. that make up the multi-layer film or packaging in cooperation with the world’s largest environmental solutions company. A demonstration pilot plant will be built in 2021, and, moving forward with LCA (Life Cycle Assessment) appraisals, cost simulations, and other verifications. Toyo Ink Group plans to start a post-industrial recycling business (*3) in 2022, and also plans to start a post-industrial and post-consumer recycling (*4) business in commercial plants by 2025.

In addition to acquiring exclusive marketing rights in Japan and first refusal rights in Asia and Europe related to major product materials related to this technology, ITOCHU will widely provide environmental solutions to food and consumer products company, retailers, brand owners, and more through requests to build structures for material recycling using this technology and to design recyclable, environmentally-friendly packaging.

Through this initiative, both companies will make currently un-recyclable multi-layer film packaging into a recyclable product, aiming for a more than 40% (*5) material recycling rate in Japan and abroad.

ITOCHU positions ESG as a key focus in the facilitation of its businesses. With the combination of this initiative with the ITOCHU Group’s network in Japan and abroad, we will create a new business model in the field of recycling and pursue the establishment of a recycling-oriented society and the sustainable development of the world.

- *1Refers to a recycling method that aims to reuse waste as raw materials for products.

- *2According to research by Toyo Ink. The first technology in the world to separate and recycle ink, adhesive, and more that make up multi-layer film materials and packaging in a single process.

- *3Refers to the recycling of raw waste materials that are produced through the production process of products.

- *4Refers to waste that is collected after consumers have used a product.

- *5For example, the current material recycling rate in Japan is about 27%, and this aims to raise this rate by about 1.5 times.

Toyo Ink SC Holdings Co., Ltd. Corporate Profile

| Company name | Toyo Ink SC Holdings Co., Ltd. |

|---|---|

| Representative | Satoru Takashima, President, Representative Director, and Group COO |

| Head Office | 2-1, Kyobashi 2-chome, Chuo-ku, Tokyo |

| URL | https://schd.toyoinkgroup.com/en/index.html |

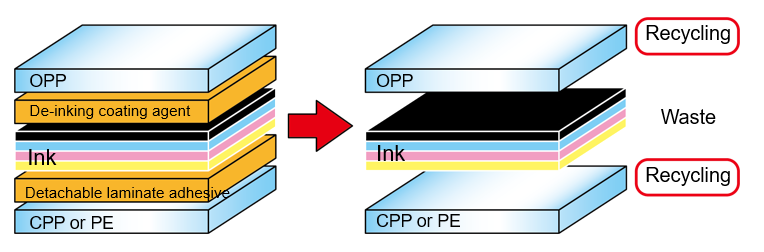

About the Multi-layer Film Separation Technology

Mainly OPP, CPP, PE, and other olefin-based film is removed and the materials are recycled through use of a de-inking coating agent and a detachable adhesive.

|

|

Photos of Film Packaging After Separation

|

Film packaging waste (shredded) |

After separation |