ITOCHU Announces Collaboration with Australia-Based MCi on the Utilization of Mineral Carbonation Technologies

May 6, 2021

ITOCHU Corporation (headquartered in Minato-ku, Tokyo; Keita Ishii, President & COO; hereinafter “ITOCHU”) announced today that it has entered into an agreement with the Australia-based company Mineral Carbonation International (headquartered in Canberra, Australia; Marcus Dawe, CEO & Managing Director; hereinafter "MCi") to collaborate on projects to apply carbon utilization technology (a technology to curb CO2 emissions by reacting industrial wastes like slag produced in the steelmaking process, coal combustion ash produced by thermal power plants or other industrial wastes contain magnesium or calcium such as waste concrete with CO2 and thus producing valuable carbonate materials).

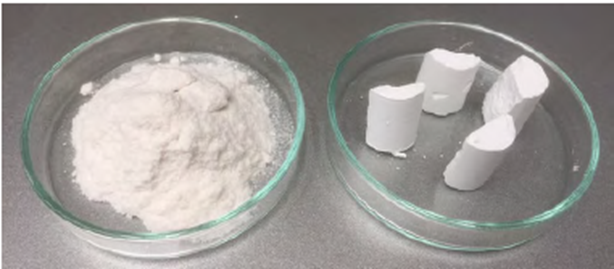

MCi’s carbon utilization technology produces calcium carbonate, magnesium carbonate, Silica and other useful solid products by combining by-products of the steelmaking process (slag),coal ash produced by thermal power plants or other industrial wastes contain magnesium or calcium such as waste concrete with CO2 to permanently lock away CO2 in a solid form. Carbon utilization has attracted attention from the steel, cement and electricity industries as a technology that could accelerate the global trend towards decarbonization.

In addition to effectively utilizing by-products (slag) and coal ash which have traditionally been processed as waste, materials such as the calcium carbonate manufactured using this technology also serve as raw material for cement, concrete and other construction materials, and are thus expected to cut CO2 emissions in the building, construction and manufacturing industries.

◆CO2 utilization technologies offering high economic efficiency without requiring CO2 separation or recovery processes

Since it was established in Australia in 2013, MCi has pursued research and development into CO2 utilization technologies and possesses some of the world's foremost technologies and knowledge in the field.

Specifically, MCi's major strengths lie its breakthrough low energy process that has the ability to skip CO2 separation and recovery processes (processes to separate and recover only CO2 from gases containing CO2 from industry) that have been essential to similar technologies in the past*, along with its ability to permanently bind CO2 in useful solid products without the use of chemicals. The approach has potential to be scaled to achieve significant cuts in CO2 emissions from industrial sectors such as steel, cement, mining and manufacturing.

Through demonstration testing at a MCi pilot plant operated with the support of the Australian Commonwealth and New South Wales Governments, MCi has already won high praise in Australia for the technology, with preparations now underway towards its global commercialization.

◆

Aiming to achieve early commercialization utilizing MCi's technologies and ITOCHU's network

As part of the "Green Growth Strategy Through Achieving Carbon Neutrality by 2050" being promoted by the Japanese government, carbon recycling has been positioned as vital to the creation of a carbon neutral society through technologies to effectively utilize CO2 as a resource," and there is expected to be high demand for these carbon capture & utilization (CCU) technologies. Looking ahead, ITOCHU will use the signing of this latest collaboration agreement as an opportunity to leverage its network in Japan while introducing and selecting candidate sites for MCi demonstration plants with the aim of scaling up and commercializing the technology with industrial customers. ITOCHU will seek to match this technology with the demand for CO2 emissions reductions in Japan, helping to solve the CO2 emissions issues faced by the companies with which it does business.

The global market for CO2 separation, capture and utilization is forecast to grow to around 6 trillion yen in 2030 and to around 10 trillion yen by the year 2050. In the future, ITOCHU will consider capital participation in MCi with the aim of business expansion, along with the rollout of the technology both inside and outside of Japan.

- *For gases that meet a certain CO2 concentration.

|

MCi's pilot plant in Newcastle, Australia |

|

MCi products (from left: magnesium and calcium carbonate in which CO2 has been locked away) |

Above: Low emissions concrete bar using MCi’s products as a supplementary cementitious material. MCi’s products can be used by existing concrete manufacturers to lower their CO2 emissions |