ITOCHU Announces Conclusion of Memorandum of Understanding with Resonac Corporation to Jointly Study Used Plastic and Textile Recycling

March 29, 2023

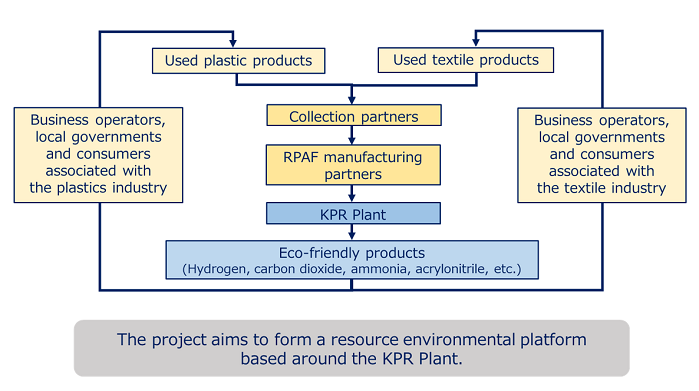

ITOCHU Corporation (headquartered in Minato-ku, Tokyo; Keita Ishii, President & COO; hereinafter “ITOCHU”) announced today that it has concluded a memorandum of understanding with Resonac Corporation (headquartered in Minato-ku, Tokyo; President & Chief Executive Officer: Hidehito Takahashi; hereinafter “Resonac”) regarding a joint study aimed at promoting a used plastic and textile recycling business utilizing a plastic chemical recycling plant (Kawasaki Plastic Recycling, hereinafter “KPR”)*1 located at the Resonac Kawasaki Plant. First, as part of the ARChemia recycling project ITOCHU will develop in coordination with Resonac, recycled solid raw materials containing a mix of used plastics and textiles known as RPAF*2 will be supplied to Resonac and transformed into chemical products such as low-carbon ammonia, solving the social issue of waste while contributing to the development of a recycling-oriented society.

Recently, there has been a growing awareness of sustainability as climate change caused by greenhouse gases has become a global issue, creating an urgent need to address the issues of disposal plastics in Japan and abroad. In Japan, while 86% of all plastic waste is recycled, 63% of it relies on thermal recovery, which means the waste is not being recycled as a new resource. In addition, in the textile industry the disposal of clothing in large volumes has become an issue, necessitating the establishment of resource recycling mechanisms.

Resonac has been converting used plastic into gas since 2003, and began operations at KPR to recycle this waste into hydrogen and other materials. Low-carbon ammonia, which is manufactured from extracted hydrogen at KPR, utilizes used plastic as a raw material, and since fossil fuel-derived energy is not used in the manufacturing process, it has achieved CO2 emission reductions of over 80%*3. However, the partial combined use of hydrogen derived from natural gas in the ammonia manufacturing process was an issue.

In this joint study, the ARChemia recycling project will be launched, with ITOCHU providing RPAF, a recycled solid raw material made from a mixture of used plastics and used textiles, to help Resonac switch to 100% waste derived raw materials. Utilizing its extensive network in the chemical and textile sectors, ITOCHU will pursue a collaboration for RPAF manufacturing with intermediate processors based on the collection of used plastics and clothing.

In December last year, demonstration testing conducted by UNICO Corporation (a wholly owned subsidiary of ITOCHU; hereinafter “UNICO”) found that RPAF utilizing multiple types of used uniforms handled by UNICO can be used as a raw material for low-carbon ammonia.

In the future, ITOCHU will promote joint ventures with Resonac not only to supply RPAF but as part of its exit strategy. To date, ITOCHU has developed biomass plastics utilizing international certification and developed various chemical recycling projects with partner companies as environmental businesses in the area of chemicals. ITOCHU regards this initiative with Resonac as important among the series of environmental businesses it pursues, and in addition to the collection and utilization of waste, will also cooperate with the sale of chemical products with high environmental added value, such as the low-carbon ammonia produced by the plant. In addition, ITOCHU is also looking to the effective utilization of the collected waste for other uses, and will explore collaboration with various partner companies through the ARChemia Project.

ITOCHU has declared “enhancing our contribution to and engagement with the SDGs” as one of the basic policies of its Medium-term Management Plan, and through the collection and recycling of used plastics and clothing with Resonac and partner companies participating in the ARChemia Project, it will contribute to the development of a recycling-oriented society.

-

*1Kawasaki Plastic Recycling: KPR

Utilizing the used plastic generated from households and companies as a raw material, it is gasified at a high temperature and broken down at the molecular level to extract hydrogen and CO2. The hydrogen extracted here is mainly used as a raw material for low-carbon ammonia, while the CO2 is not released into the atmosphere, and is instead recycled as a raw material used by the Resonac Group company Resonac Gas Products for dry ice, carbonated beverages and carbon dioxide gas for medical use. Also note that KPR is the world’s only plant that has been engaged in the stable operation of gasification-based chemical recycling over a long period of nearly two decades. -

*2RPAF: Refuse-derived Plastic, Paper and Apparel Densified Feedstock

A solid raw material for gasification-based chemical recycling adjusted for calorie generation, made mainly from used plastics, used paper and used textiles. -

*3Resonac press release dated December 20, 2022

Showa Denko’s Low-Carbon Ammonia Produced from Used Plastics Reduces CO2 Emission by more than 80%

- SDK’s low-carbon ammonia shows excellent environmental performance verified by a calculation method endorsed by a third party-

ARChemia Project logo

|

|

ARChemia Project Outline

|

|