ITOCHU Announces Launch of Solution to Visualize and Improve of Supply Chain Issues

July 18, 2024

ITOCHU Corporation (headquartered in Minato-ku, Tokyo; Keita Ishii, President & COO; hereinafter “ITOCHU”) announced today that it has developed a data-based DX solution that provides comprehensive support, ranging from the discovery of supply chain issues to the implementation of improvement measures for efficient and sustainable supply chains*1. The solution has been launched for use by ITOCHU and its Group Companies.

In recent years, in order to improve the efficiency of domestic logistics, the Japanese government has been urging shippers, businesses, and consumers to change their behavior by formulating “Policy Package for Logistics Innovation” and amending two laws related to logistics. In particular, as certain shippers*2 will be required to improve the efficiency of their logistics operations, it will become even more crucial for them to fully understand the structure of their supply chains, identify issues, and evaluate the effectiveness of improvement measures based on data.

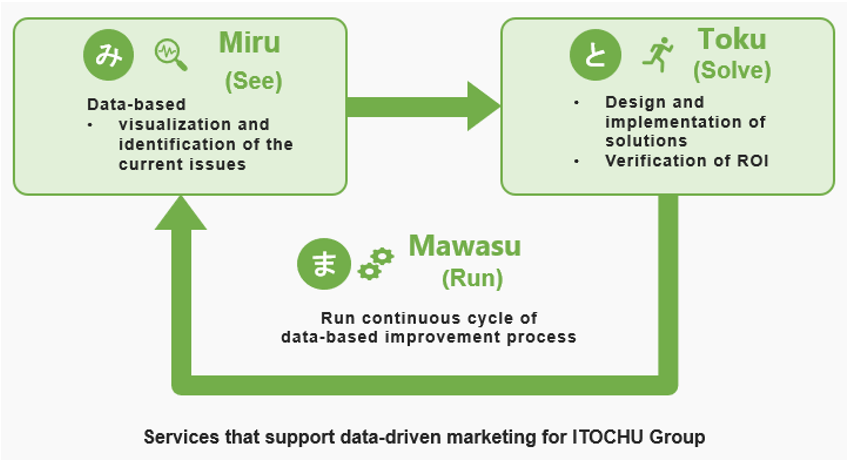

In 2018, ITOCHU created Data Lake, a company-wide integrated data platform. Following this, the company established the BICC,*3 an organization focused on data analysis. Through BICC, ITOCHU has been supporting to ITOCHU and its Groupe Companies in solving supply-chain issues based on data, and ITOCHU will now launch the “Supply Chain Miru-Toku-Mawasu Service” (commonly known as “SC Mi-To-Ma Service”), a data-based DX solution for supply chain operations. In Japanese, ‘Miru’, ‘Toku’, and ‘Mawasu’ mean ‘see’, ‘solve’, and ‘run’, respectively.

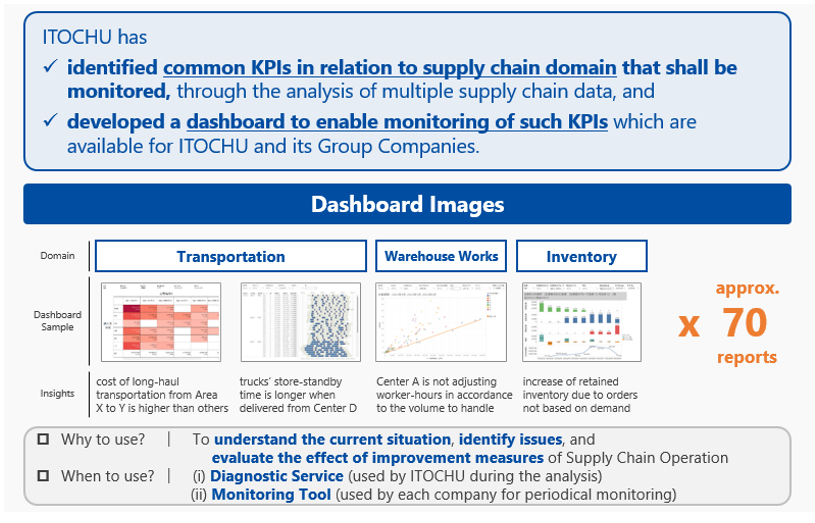

This service utilizes about 70 types of dashboards*4, developed together with BrainPad Inc. and Logi Cross Communication Inc., which enables to visualize various supply chain KPIs. By utilizing such dashboards, the service will help (i) identify supply chain issues by combining relevant supply chain data (e.g. delivery times, labor costs of warehouse work, backlogged inventory) in about a month through “Miru (See)”, (ii) implement necessary improvement measures through “Toku (Solve)”, and (iii) run the PDCA cycle through “Mawasu (Run)” in a comprehensive manner.

ITOCHU aims to realize efficient and sustainable supply chains throughout the Group and enhance corporate value by sharing supply chain issues, knowledges, and solutions within the Group, as well as identifying and resolving each company’s issues at an early stage through this service.

- *1This refers to a series of flows and processes starting from production of products/services to supply to consumers (e.g. procurement of raw materials, production, assembly of products, sales, delivery).

- *2Shippers with an annual cargo transport volume of 30 million ton-kilometers or more.

- *3This refers to the Business Intelligence Competency Center (BICC), an in-house organization that specializes in data analysis and utilization support.

- *4A BI (Business Intelligence) tool that collects and analyzes digital data accumulated by companies, as well as visualizes them in aggregate values, tables, graphs, etc., displaying multiple graphs and tables on a single screen.

|

|

|

|