Launching PT PROJECT TREE INDONESIA, a Sustainability Service Company

Continuing to enhance the traceability and sustainability of natural rubber, a crucial raw material for tire production

June 2, 2025

ITOCHU Corporation (headquartered in Minato-ku, Tokyo; Keita Ishii, President & COO; hereinafter “ITOCHU”) announced that it has established a new sustainability service company, PT PROJECT TREE INDONESIA (headquartered in Jakarta, Indonesia; Ryoichi Watabe, President Director; hereinafter “PTI”), which commenced operations in June 2025. Going forward, ITOCHU will continue to support the PROJECT TREE*1 initiative aimed at improving the sustainability of natural rubber through PTI and contribute to the enhancement of the sustainability of the entire industry.

Natural rubber is a natural resource that is vital in modern society. About 70% of global natural rubber consumption is in the production of tires, while approximately 85% of global production relies on smallholders. Southeast Asia, including Thailand and Indonesia, stands out as a major production region. The existing agricultural management practices among smallholders face several limitations including challenges related to illegal logging, human rights issues, inexpert farming techniques and other concerns.

In Europe, the introduction of the European Deforestation Regulation (hereinafter “EUDR”) has increased the urgency of the industry’s sustainability efforts. Effective December 30, 2025, companies importing natural rubber and tire products into the EU will be required to prove that their products do not contribute to deforestation, making environmental and human rights compliance more critical than ever.

ITOCHU promptly began addressing environmental and social issues within the natural rubber industry in collaboration with its natural rubber processing subsidiary, PT. Aneka Bumi Pratama (headquartered in South Sumatra, Indonesia; Ryotaro Hayashi, President Director; hereinafter “ABP”). In 2019, ITOCHU launched a pilot project using blockchain technology to build a traceability system. This system was commercialized in 2021 as PROJECT TREE. ABP has already established a stable supply system for rubber that complies with the EUDR requirements.

PROJECT TREE also supports smallholders by implementing an incentive-based reward system and providing agricultural training programs. Over the past four years, the initiative has delivered agricultural training program to approximately 23,000 farmers, aimed at enhancing agricultural practices. Participation in PROJECT TREE has continued to expand each year, with tire manufacturers, imported car dealers and bus companies now among its supporters and collaborators.

To date, PROJECT TREE has been promoted through ABP. However, with the establishment of PTI, the initiative will expand beyond ABP’s supply chain to include other natural rubber processors, enabling broader sustainability efforts throughout the industry. PTI will train professionals to lead initiatives, further promoting the use of EUDR-compliant rubber and driving progress toward the sustainability of the entire natural rubber industry.

ITOCHU has put forth a new management policy, “The Brand-new Deal – Profit opportunities are shifting downstream –” and is pursuing a policy of enhancing its contribution to and engagement with the SDGs through business activities while listening to all stakeholders, including the market, society, and consumers.

(Reference)

PROJECT TREE website

https://project-tree-natural-rubber.com/

|

image1. Concept of PROJECT TREE |

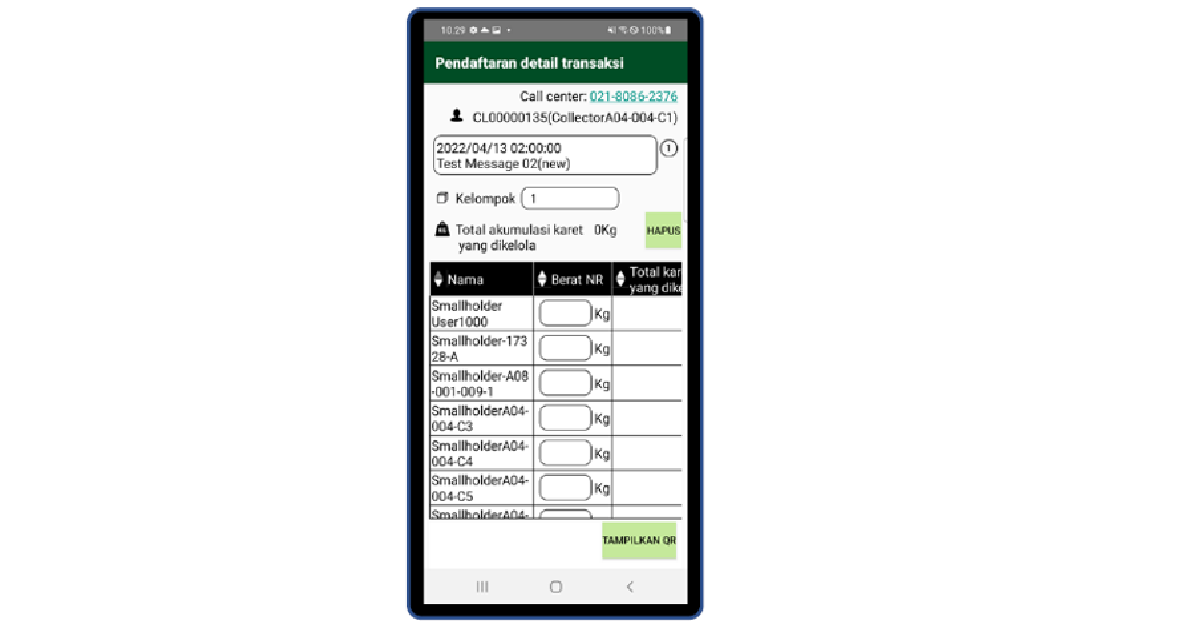

image2. Screen of Smartphone App |

image3. Map of Plantation |

|

*1 PROJECT TREE : Transparent Rubber Ecosystem for Earth PROJECT TREE is promoted by ITOCHU with the goal of improving origin traceability and sustainability in the natural rubber industry. A smartphone app-accessible production area tracking system developed by ITOCHU records information such as the contents, time, date and location of transactions using blockchain technology and shows this information on a map. These raw materials are processed apart from other materials and sold to tire manufacturers as natural rubber whose origin can be certified. One feature of this system is that it distributes a part of the support money from stakeholders that identify with the project to raw material suppliers and also provides smallholders who do not have smartphones or bank accounts with farm tools, fertilizers and training to increase productivity. In addition, ITOCHU will implement a series of improvement plans based on the results of its supply chain risk assessments. These assessments are carried out in consultation with the international NGOs, Proforest and SNV, who also audit them. The goals of PROJECT TREE are to enable all natural rubber stakeholders, including natural rubber processing companies, tire wholesalers and retailers, automobile manufacturers and consumers to be involved in the project and distribute the tires manufactured through cooperative production around the world. PROJECT TREE is also expected to contribute to the policies and the achievement of the goals of the Global Platform for Sustainable Natural Rubber (GPSNR), a recently established global platform for the production of sustainable natural rubber. |