ITOCHU Announces Initiatives to Promote the SDGs for Mine Operations in Metal and Mineral Resources

Memorandum on Decarbonization and Operational DX with Brazilian CSN Group

June 14, 2021

ITOCHU Corporation (headquartered in Minato-ku, Tokyo; Keita Ishii, President & COO; hereinafter “ITOCHU”) announced today that a memorandum on SDGs collaboration has been signed with the Brazilian CSN Group as a model case for initiatives, along with the implementation of business partnerships with companies in Japan and abroad that possess excellent technologies, with the aim of promoting decarbonization and digital transformation (hereinafter, "DX") in the field of metals and mineral resources. ITOCHU owns Brazilian iron ore mining interests (Casa de Pedra [CdP] Mines) together with the CSN Group and we have agreed on collaborating in decarbonization and DX to increase operational efficiency at the CdP Mines and to contribute to decarbonization at the Mines and CSN steel work. Moreover, ITOCHU also plans to conduct broader collaboration, including current ITOCHU decarbonization initiatives in the field of metals and minerals (*1), as a way to further contribute to decarbonization of CSN Group operations, such as through low-carbon ironmaking technology, hydrogen and ammonia, and CCUS.

DX initiatives

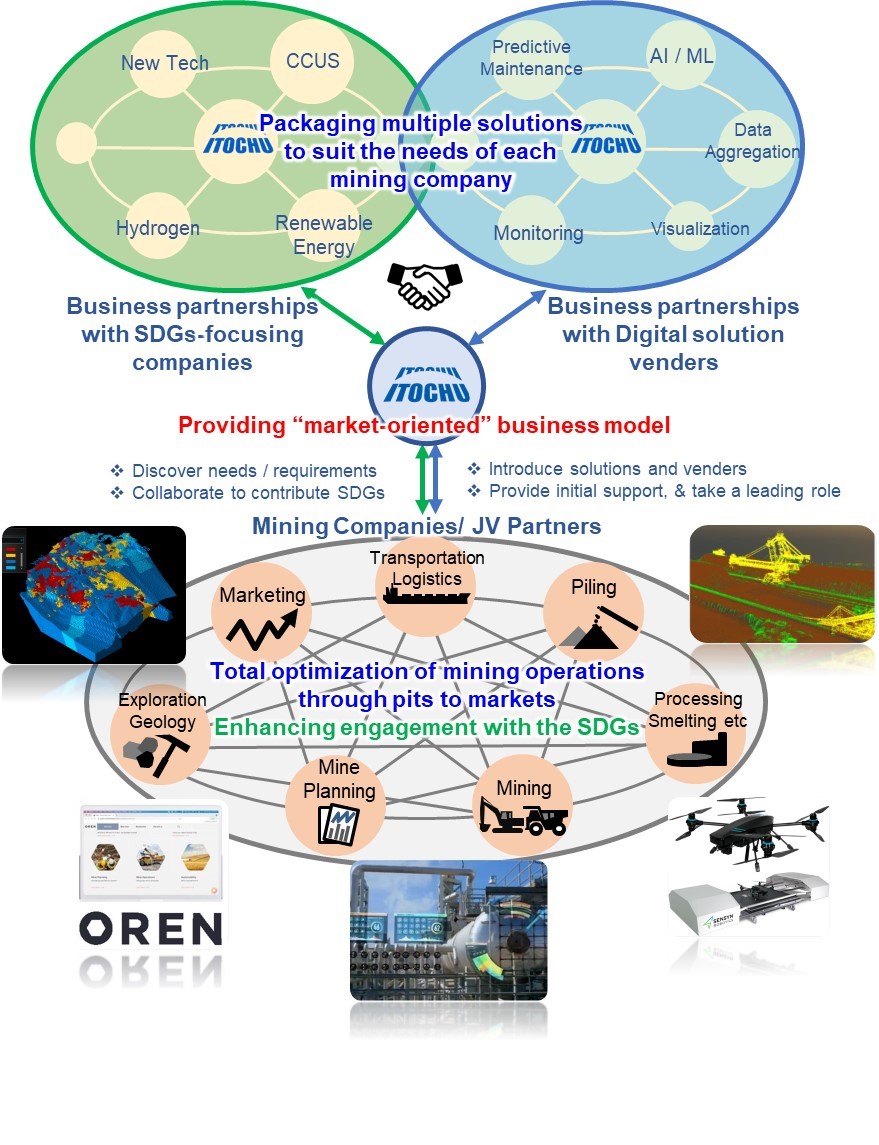

To promote digital transformation to improve operational efficiency, cut costs, and increase safety in metal and mineral resources, ITOCHU has entered into business partnerships with companies (solution vendors) in Japan and abroad that possess excellent digital solutions, know-how, and track records with regard to improving all the relevant processes. *2 See annexed table for a list of principal partners

ITOCHU will utilize the networks in the metal and mineral resource industry that it has built through previous interest investment and management as well as trade business to discover DX needs, introduce them to solution vendors, and take a leading role in DX matters, focusing primarily on mines where ITOCHU owns interests. It will also offer packages of multiple solutions to suit the needs of each mining company as well as make recommendations and provide initial support to those companies.

Moreover, its aim is also to provide solutions that support the SDGs, such as decarbonization of operations through DX-mediated emissions control and increased safety through more sophisticated monitoring.

Memorandum on collaboration to start digitization project with Brazilian CSN Mineracao (CM) as well as for decarbonization and operational DX with the CSN Group

As a model case of these initiatives, ITOCHU together with GE Digital started a DX project for operations at a CdP Mine in April 2021. In the first stage of this project, the plan is to implement solutions to visualize operational data and administrative and financial data for managers as well as to conduct preventive maintenance at plants and relevant equipment and to analyze and improve the efficiency of operations. It is expected to contribute to improving business profitability mainly through cost reductions and improvement in metal recovery rate. In the second stage and beyond, the aim is for further efficiency improvement by linking data from mines to ports as well as more advanced data linking of ITOCHU functions and market information.

In addition to its collaboration for operational DX, in line with the growing global interest in decarbonization, ITOCHU aspires to contribute to cutting CO2 emissions at CdP Mines and other CSN businesses such as ironworks. As such, it has signed a memorandum with CSN, CSN Mineracao, and CSN Inova (the CSN Group) to work together for the SDGs and jointly investigate and potentially invest in new technologies. We agreed to implement initiatives for operational DX and decarbonization in the CdP Mine model case. In the future, it plans to jointly expand to third-party mines and businesses on the basis of the model case.

ITOCHU positions "Strengthening Contributions to and Initiatives for the SDGs" as one of its basic policies in the medium-term management plan Brand New Deal 2023. Centering on mines where it has interests, it will contribute to improving operational efficiency in the metal and mineral resource industry as a whole, increasing safety, and achieving the SDGs.

-

*1Major decarbonization initiatives in metals and minerals

・February 24, 2021: ITOCHU Announces the Building of a Local Hydrogen Production for Local Consumption Model Business in Northern Kyushu

https://www.itochu.co.jp/en/news/press/2021/210224.html

・May 6, 2021: ITOCHU Announces Collaboration with Australia-Based MCi on the Utilization of Mineral Carbonation Technologies

https://www.itochu.co.jp/en/news/press/2021/210506.html

*2 Annexed table: Principal partners (solution vendors)

| Company | Location | Solution description to be utilized in mining industry |

|---|---|---|

| GE Digital | Global | They provide Asset and Process Optimization solutions including Digital Twins to help organizations better integrate, automate and standardize core operational work processes, safely improving production efficiency while eliminating wasteful costs. |

| Shell | UK |

Shell offers its sectoral expertise in decarbonisation and digitalisation pathways to find solutions that meet the specific needs in the industry as well as needs of ITOCHU’s Metals and Minerals portfolio and its clients across the globe. A key Shell offering is Oren, the first B to B digital marketplace developed in conjunction with IBM, which offers about 60 digital and technology solutions for mining companies. This marketplace provides a broad range of solutions from enterprise companies and innovative start-ups, including hardware solutions such as IoT sensors and software solutions such as the utilization of AI to improve operation efficiency and to optimize inventory management and to support mines to achieve SDGs. |

| MineRP | South Africa |

MineRP provides an integration platform which consolidates the data from all the disconnected expert mining technical systems onto a Digital Twin of the entire mine and all its assets. The MineRP Platform enables mining companies to rapidly create and test and implement mine planning alternatives, which leads to shorter planning cycles and more realistic plans. MineRP is the ultimate platform to digitalize mine planning and execution for the mine of the future. |

| SensynRobotics | Japan | They provide the solutions with utilization of robotics technology, such as drones for mining companies to make inspection or monitoring work remote, more efficient and more safety. They have sufficient foot print in heavy industries and in mining industry their solutions are expected to be utilized to inspect plants and monitor and manage yard stock pile. |

| Scan X | Japan/ Australia |

They provide cloud base system which can automatically process point cloud data collected by LiDAR, and can classify them, remove unnecessary data and extract specific items by utilizing Machine Learning and the solution enable mining companies to improve accuracy of pit monitoring and to improve safety. |

|

|