ITOCHU Announces Launch of Pilot Project for Cellulose Nanofiber-Reinforced Plastic Logistics Materials

Demonstration at approximately 80 FamilyMart stores in Shizuoka Prefecture

July 18, 2025

ITOCHU Corporation (headquartered in Minato-ku, Tokyo; Keita Ishii, President & COO; hereinafter “ITOCHU”) today announced the launch of a joint demonstration project for cellulose nanofiber (CNF) reinforced plastic logistics containers in collaboration with FamilyMart Co., Ltd. (headquartered in Minato-ku, Tokyo; Kensuke Hosomi, Representative Director and President; hereinafter "FamilyMart”), SANKO Co., Ltd. (headquartered in Mizuho, Gifu; Toshihiko Goto, President and Representative Director; hereinafter “Sanko”), and the Research Institute for Sustainable Humanosphere, Kyoto University (headquartered in Uji, Kyoto; Mamoru Yamamoto, Director; hereinafter “Kyoto University”). The pilot demonstration project has already been selected for the FY2025 Cellulose-based Circular Economy Business Demonstration Project*1 by Shizuoka Prefecture. This initiative will run for approximately six months from August 2025 at about 80 FamilyMart stores in Shizuoka to verify the performance of CNF-reinforced plastic containers.

CNF*2 is produced from sustainably sourced wood and imparts high-performance characteristics such as strength and recyclability. Although the global CNF market size was estimated at only 6 billion yen in 2024,*3 it is expected to see significant growth as a sustainable biomass-based alternative to replace fossil-based materials for decarbonization. Research institutes such as universities and companies in Japan have played a pioneering role in CNF research and development. However, commercial applications of CNF remain limited due to high cost and other challenges. The project aims to move forward the transition of the advanced material from R&D stage to commercial-scale industrial use.

ITOCHU has recently begun developing CNF-reinforced plastic logistics materials in collaboration with Sanko, the largest plastic logistics material manufacturer in Japan. CNF provides a sustainable solution by enabling the production of thinner, lighter and stronger plastic logistics containers. In response to current logistic challenges, FamilyMart, the second largest convenience store chain in Japan, decided to join the demonstration project prioritizing workload reduction and loading efficiency improvements. This initiative will mark the world's first implementation of CNF-reinforced plastic materials in a retail store setting.

The product developed in this project is a logistics material known as a shallow container (commonly known as a bat) for food transportation.*4 Sanko will produce CNF-reinforced plastic shallow containers. FamilyMart will use them for chilled food transportation to about 80 stores in Shizuoka. In addition, Specially Appointed Professor Hiroyuki Yano, Kyoto University, one of the world-renowned authorities on CNF, will support its product performance assessment, environmental assessment and product engineering. The consortium will aim to achieve a reduction in thickness and weight of more than 15% and to explore other logistics applications.

Under its management policy, “The Brand-new Deal – Profit opportunities are shifting downstream –,” ITOCHU is pursuing a broad range of research with a market-oriented perspective ranging from industrial applications to luxury goods.*5 ITOCHU will continue to expand applications of CNF, aiming to realize a sustainable society through the dissemination of CNF.

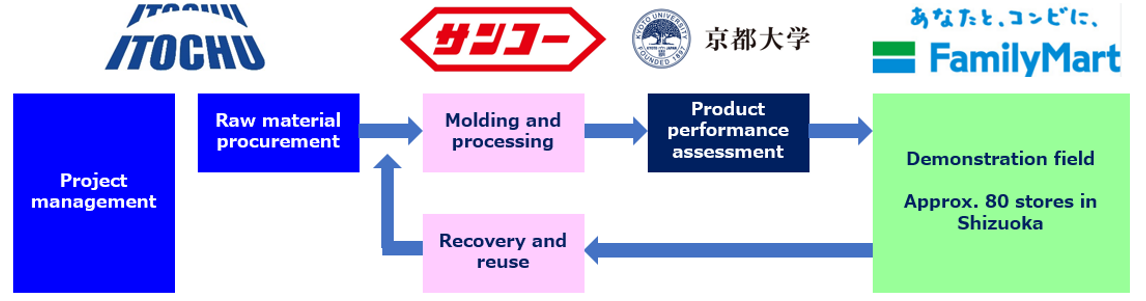

Scheme

|

|

Consortium members and role of each organization

| Organization name | Role |

|---|---|

| ITOCHU Corporation | Project management (representative of the consortium) and raw material procurement |

| FamilyMart | Implementation of CNF-based logistics material at stores and warehouses in Shizuoka |

| Sanko | Production and recycling of CNF-reinforced plastic logistic materials |

| Kyoto University | Product performance assessment, environmental assessment, and product engineering |

*1 Shizuoka Cellulose-based Circular Economy Business Demonstration Project | official website of Shizuoka Prefecture

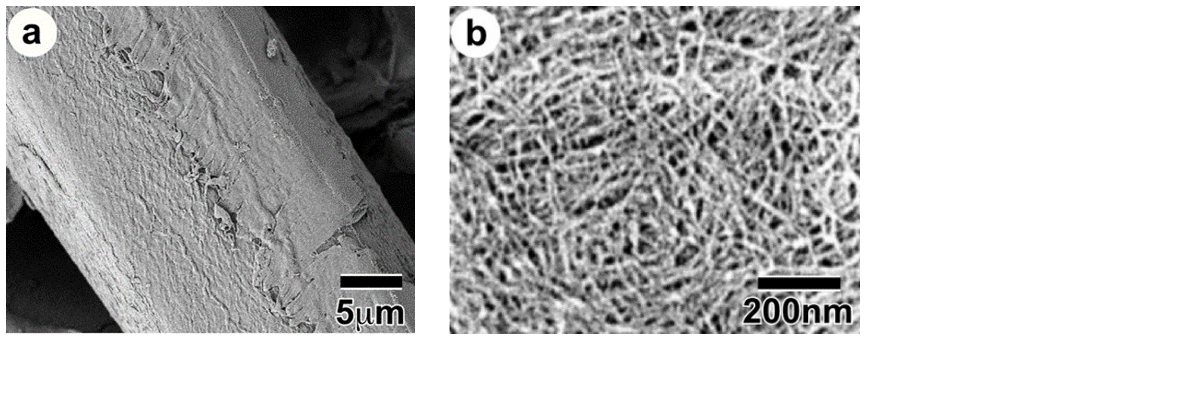

*2 Cellulose nanofiber (CNF) is a material made from mechanically and chemically processing cellulose, the main component of plants, to break it down to the nanometer scale (nano = 1/1 billion). Raw materials of CNF are derived from sustainably available wood. The advanced material is expected to be compounded with resin and other materials, excelling in strength and recyclability.

(a) Cellulose fiber, (b) CNF (provided by Specially Appointed Professor Hiroyuki Yano, Kyoto University)

|

|

*3 CNF market size: The survey was performed with respect to the global cellulose nanofiber market in 2024.

*4 Shallow container: Thin transporting container mainly used for food transportation. It is currently made of plastic.

|

|