Enhancing Our Contribution to and Engagement with the SDGs Through Business Activities

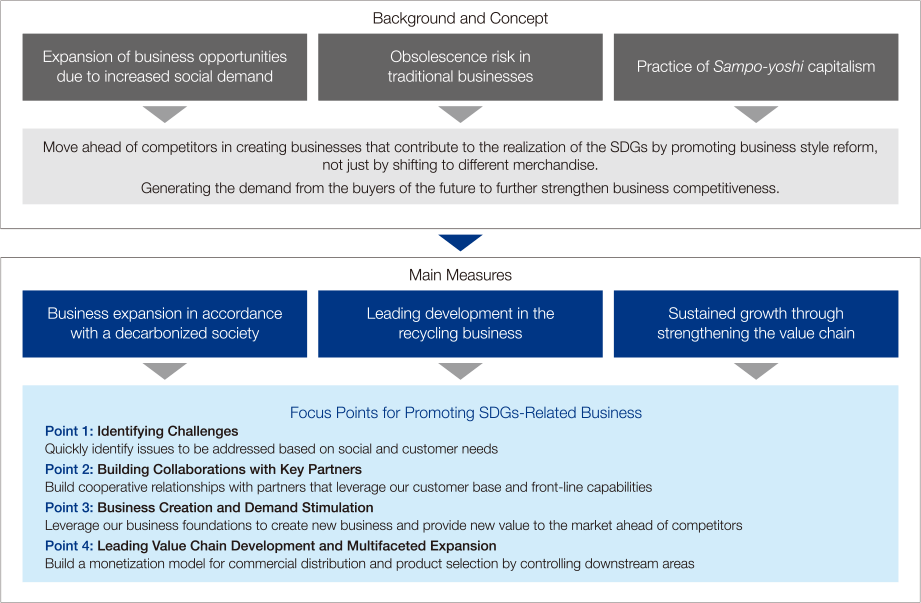

Enhancing Competitiveness by Creating Business that Helps Achieve the SDGs

ITOCHU sees opportunities in the trends of the SDGs, which are impacting even basic business structures. Utilizing our existing business base, centered on our strong non-resource sector, we are addressing the needs of society and customers, and steadily connecting this to our evolving profit model.

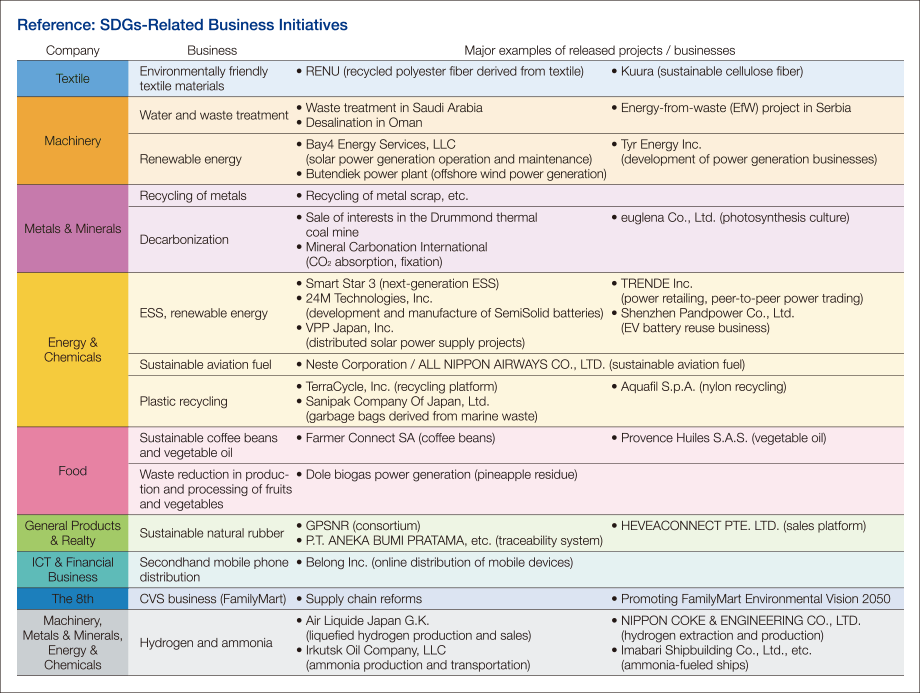

In addition, we will continue contributing to the realization of decarbonization across society, ahead of others in the industry, by completely withdrawing from thermal coal interests and developing such businesses as the energy storage system (ESS) business, which is a growth field.

Business expansion in accordance with a decarbonized society

•Complete divestment from thermal coal interest through the sale of interests in Drummond and other assets

•Building a next-generation fuel value chain using hydrogen and ammonia

(Creating new business opportunities utilizing existing business foundations, such as the development of hydrogen stations)

•Development of a distributed power supply platform using AI-equipped ESS, of which we boast the top sales volume in Japan

(Establishment of new economic zones by optimizing the balance of electricity supply and demand in households and communities and by realizing environmental value trading)

Leading development in the recycling business

•Leading the plastic recycling business by leveraging our customer base of more than 10,000 companies

(Providing solutions based on new technologies in response to consumer and social needs, simultaneously addressing environmental and business considerations)

•Business expansion and business transformation of water and waste treatment businesses with competitive advantages

(Utilizing our knowledge in Europe to expand our business to the Middle East and Asia and to highly profitable waste recycling, etc.)

Sustained growth through strengthening the value chain

•Increasing added value throughout product distribution with the industry’s first natural rubber traceability system (Standardization of natural rubber to eliminate illegal logging and other issues, and deploying it throughout Group operations spanning rubber processing to tire retail)

•Improving productivity and reducing food loss by optimizing FamilyMart supply chains and enhancing logistics efficiency

Approach to SDGs-Related Businesses