Natural Capital and Biodiversity (Information Disclosure Based on the TNFD Recommendations)

Policy and Basic Approach on Natural Capital and Biodiversity

ITOCHU invests in businesses and trades globally from raw materials and other areas of the upstream processes to the downstream processes. We depend heavily on renewable and non-renewable natural capital which benefits people such as plants, animals, the air, water, land and minerals. Our businesses may also have a negative impact on that natural capital.

We see addressing global environmental issues, including natural capital and biodiversity, as a top management priority. Accordingly, we have established the following Biodiversity Policy to promote conservation of biodiversity as indicated in the ITOCHU Group Environmental Policy to realize the ITOCHU mission of Sampo-yoshi (good for the seller, good for the buyer and good for society). Based on the Biodiversity Policy, we will continue to contribute to the realization of a sustainable society. We are also engaged in initiatives in business-related areas as part of our social contribution activities in communities.

Biodiversity Policy

Biodiversity-friendly Environmental Management

We recognize that our business activities depend on the blessings of biodiversity and that they may affect the ecosystem. Accordingly, we shall promote environmental management that incorporates a wide range of environmental activities (such as interrelated climate change measures, resource circulation measures and biodiversity conservation) into our business activities to build a society in which we coexist with nature.Understanding and Reducing the Impact of the Relationship between Business and Biodiversity

We are aiming for a net positive impact on biodiversity by understanding the relationship between our business activities not only in our group companies but across our entire group and biodiversity from a global perspective. We shall strive to avoid and minimize the impact our business activities have on biodiversity. At the same time, we shall promote the restoration of the ecosystem.

We have established a procurement policy to protect natural forests and forest resources concerning forest commodities (such as timber, natural rubber, and palm oil). We shall promote information gathering to confirm there is zero deforestation due to production from protected areas designated by law.Compliance with International Treaties and the National Laws of Each Country

We shall promote the conservation of biodiversity by complying with international treaties on biodiversity (e.g., the Convention on Biological Diversity) and the relevant national laws of each country.

We shall promote social contribution activities to protect endangered species in the areas in which we conduct business activities. This is in addition to not participating in transactions relating to endangered species designated by the Washington Convention (CITES)* with our business activities.Enhancement of Partnerships and Conservation of Local Ecosystems

We shall look to share awareness of biodiversity by cooperating with industry groups, supply chains, NGOs, and international organizations. We shall then make our biodiversity conservation efforts more effective.

We shall take into account conservation of biodiversity in the areas in which we conduct business activities. At the same time, we shall promote conservation of biodiversity from the perspective of creating communities that utilize natural resources to contribute to the realization of affluent and safe lives in local communities. We shall do this together with stakeholders such as local residents and NGOs in addition to governmental bodies.Enhancement of Information Sharing and Dissemination

We shall promote understanding of biodiversity to local residents of the areas in which we conduct business activities in addition to our employees through awareness activities.

We shall contribute to raising awareness of biodiversity over the whole of society by continuously disclosing the details, targets and achievement status of our efforts.

- CITES: Convention on International Trade in Endangered Species of Wild Fauna and Flora

Fumihiko Kobayashi

Member of the Board

Executive Vice President

Chief Administrative Officer

Established in April 2022

Governance

Governance for Nature-related Issues

ITOCHU acknowledges addressing sustainability issues, including natural capital and biodiversity, as one of our key management issues. Therefore, our Board of Directors deliberates and makes decisions on important matters such as policies to address nature-related risks and opportunities, and annual budgets and business plans which take into account risks and opportunities.

We have given the Sustainability Committee the overall management responsibility for planning and implementing various measures to address sustainability-related matters including natural capital and biodiversity. Our Chief Administrative Officer (CAO) is a Director with responsibility for nature-related issues. Together with this, the CAO is a member of the Headquarters Management Committee (HMC) at the executive level. The CAO also serves as the Chair of the Sustainability Committee. The CAO reports the matters deliberated and decided on by the Sustainability Committee together with the situation of the main activities to promote sustainability to the Board of Directors about twice a year. The Board of Directors considers the matters deliberated and decided on by the Sustainability Committee according to those reports. Through these procedures, the Board of Directors appropriately oversees the promotion of business and investment strategies to address environmental and social risks and opportunities. This includes reviewing those strategies and making asset replacement decisions. Moreover, the managers in each company and Headquarters’ administrative division who also serve as ESG officers also participate as core members in the Sustainability Committee at the executive level. The Sustainability Committee receives reports about natural capital and biodiversity-related matters from the Sustainability Management Division and those in charge of promoting ESG in each company and Headquarters’ administrative division. The committee then uses those reports to manage and monitor progress on various measures and initiatives.

The Chair of the Sustainability Committee and the managers in each company (ESG Officers) hold a Sustainability Advisory Board once a year to enter into dialogue with external specialists. The Sustainability Advisory Board allows its members to grasp the expectations and demands society has in us. The members then promote its business with the consideration to those sustainability issues discussed in the Advisory Board.

Refer to: Our Sustainability-related Governance Organization

Nature-related Human Rights and Stakeholder Engagement

ITOCHU Group has established The ITOCHU Group Human Rights Policy based on the United Nations Guiding Principles on Business and Human Rights. This policy specifically expresses the Group’s concept of respect for human rights. We have used this policy to declare we will conduct human rights due diligence and enter into dialogue and discussions with potentially affected Groups and stakeholders.

We have also formulated “Respect for the Rights of Indigenous People” as an individual policy. This policy makes it clear we will respect and consider the rights of indigenous people as stipulated in the laws of the countries and regions where the Group engages in business activities and international agreements such as the “United Nations Declaration on the Rights of Indigenous Peoples” and the International Labour Organization (ILO) Convention 169. When considering a new business investment project, we strictly check in advance the impact that business will have on the rights of indigenous people. We also periodically conduct human rights due diligence even after starting that business. We conducted human rights due diligence from FYE 2020 to FYE 2025 in our food-related business (Food Company) textile-related business (Textile Company), and forest goods and materials-related business (General Products & Realty Company) with their high dependency on natural capital, and our metals-related business (Metals & Minerals Company) and consumer business (The 8th Company) with its high impact on natural capital. We have also set the impact on local communities and residents as a human rights risk indicator to be investigated.

Refer to: Human Rights

Risk and Impact Management

ITOCHU monitors the risks to our business from changes in natural capital and biodiversity in each country and business site. We manage the nature-related risks we have identified as major risks (environmental and social risks) in ITOCHU Group risk analysis. We consider and evaluate the nature-related risks we have identified during the investment decision process. We utilize risk identification, evaluation, information management and monitoring systems in each department responsible for managing these risks on a consolidated basis.

Identification and Evaluation of Nature-related Risks

ITOCHU acknowledges risk management as a key management issue. Therefore, we have established a basic risk management policy for the ITOCHU Group and develop the necessary risk management systems and techniques based on the concept of the COSO-ERM framework. As stated in the ITOCHU Group Environmental Policy, we collect information on laws and regulations related to environmental conservation and then comply with them. We have also introduced an environmental management system (EMS) based on ISO 14001. We recognize the impact our business activities may have on the environment and society. We also work to grasp the status in Group companies.

For example, we grasp and evaluate water risks at manufacturing sites using the WRI Aqueduct tool developed by the World Resources Institute (WRI). We also periodically identify and evaluate other nature-related risks in line with the frameworks established by the international organizations we mention later.

Refer to: ITOCHU Group Risk Management

Integrating Nature-related Risk Management into the ITOCHU Group Risk Management System

Due to the nature of our broad-based operations, ITOCHU is subject to various risks, including market risks, credit risks and investment risks. In addition to establishing various internal committees and designated responsible departments, we have created a risk management organizational structure and management methods necessary to address these risks. This organizational structure includes outlining management regulations, investment standards, risk limits, and transaction limits, as well as establishing structures for reporting and monitoring to enable integrated Group risk management.

Nature-related risks are one of the major risks (environmental and social risks) subject to Group risk management. We incorporate this risk management into the evaluation methods for each business phase shown in the table below, which can broadly cover our business activities including management of investment, trading products, logistics, Group companies, supply chain, business strategy, portfolio, etc.

Nature-related Risk Management Procedures and Evaluation Methods for Each Business Phase

| Business Phase | Evaluation Method |

| Business start |

|

| Business management |

|

| Review business strategy |

|

Nature-related Risk Management Systems

Business Start Phase (Evaluation of the Impact on Biodiversity for New Business Investment Projects)

ITOCHU uses the ESG Checklist for Investments to evaluate in advance the impact our business investment projects will have on the environment and society. This evaluation includes, for example, grasping the impact a project will have on the ecosystem and whether it will have an impact on the natural environment and biodiversity such as by depleting resources. If we find there will be an impact, we conduct a risk assessment. If necessary, we take measures such as requesting additional due diligence from an external specialist agency to confirm there will be no problems. Only then do we invest in the projects.

Business Management Phase (Assessment of the Impact on Biodiversity in the Value Chain)

Assessment of Sustainability Risk in Products ITOCHU Handles

ITOCHU conducts a sustainability risk assessment for each new product we will handle. We use LCA analytical methods to evaluate the impact the product will have on the environment and society, compliance with environmental laws and regulations, relationships with stakeholders, and more. This evaluation covers the stages of the product from the procurement of its raw materials to its manufacturing, use and disposal. If there is a significant nature-related risk in the value chain, we subject that product to priority management. We then formulate and implement various regulations, procedure manuals, education on the specific work operational factors, and other measures.

Sustainability Survey for Suppliers

Each Company at ITOCHU and applicable ITOCHU Group companies select important suppliers based on certain guidelines, including high-risk countries, handled products, and handled amounts, to grasp the status of our suppliers. Those in charge of sales at each Company and those in charge at overseas subsidiaries and Group companies visit those suppliers and interview them. Those in charge also conduct sustainability surveys with questionnaires on important suppliers. We check the situation of initiatives for natural capital including biodiversity. We make continuous improvements by asking suppliers to address issues as necessary.

Business Evaluation Based on the TNFD Framework

Scoping

ITOCHU participates in the TNFD Forum organized by the Task Force on Nature-related Financial Disclosures (TNFD). In order to confirm the applicability of the methodology recommended by the TNFD to us, we conducted a desktop analysis to identify the potential dependencies and impacts on natural capital across all businesses within the ITOCHU Group, using the TNFD framework as a reference. Based on this analysis, we identified high-priority businesses.

- Phase 1

-

Correlate Business Units

and Processes- Prepare the information necessary for analysis using the ENCORE database.

- Phase 2

-

Consider the Method of Evaluating the Dependency and Impact

- Consider the details of the evaluation approach.

- Phase 3

-

Map and Qualitatively Interpret the Dependency and Impact

- Map the dependency and impact for each business.

- Prepare the qualitative information to support the mapping above.

Steps of Scoping

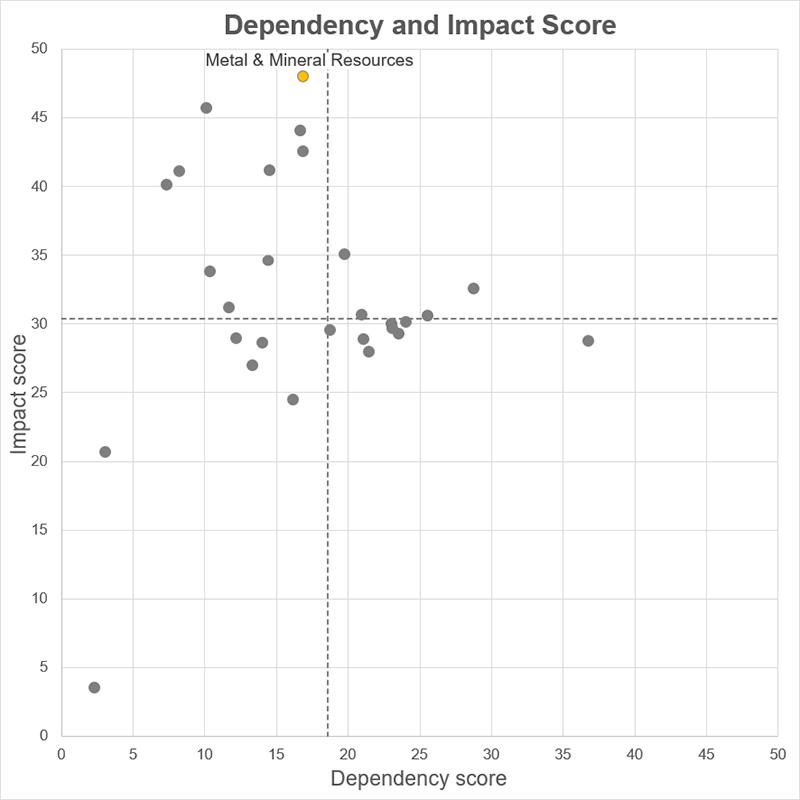

Specifically, we used the natural capital impact assessment tool “ENCORE” developed by the United Nations Environment Programme and other organizations, to categorize the activity processes along the value chain, including both upstream and downstream of our business, according to the processes defined by ENCORE. Then, by consolidating businesses with similar processes, we formed 28 groups. For each of those groups, we calculated the score for each dependency and impact while taking into account the degree of our involvement and other factors in the businesses in our value chain. We evaluated the dependency of each business on natural capital in six stages and totaled the dependency score. We also evaluated the impact in the same way in five stages and totaled the impact score. For instance, we can break down the evaluation of Metal & Mineral Resources businesses into the following elements. The average of the evaluation scores for each of these business processes is shown as the results of this analysis.

We organized these results with the impact on the vertical axis and the dependency on the horizontal axis. This gives us a map of the dependency and the impact as shown in the figure on the below.

- The dashed lines show the average dependency and impact scores of all ENCORE processes

LEAP Approach

Trial Analysis

To verify the validity of the scoping (evaluation of all businesses) using ENCORE and to deepen our understanding of dependencies and impacts on natural capital, as well as the risks and opportunities arising from them, ITOCHU conducted a LEAP approach*1 on our high-impact businesses. The LEAP approach comprehensively evaluates the natural capital-related issues advocated by the TNFD.

- Locate

-

- Determine the scope of analysis. Next, identify the activity areas of your businesses and value chains. Identify sensitive locations with high priority from biodiversity and water risk perspectives.

- Evaluate

-

- Identify the dependency and impact on natural capital in the sensitive locations with high priority.

- Evaluate the ecosystem services, impact drivers and related natural capital to evaluate the size and scale of important dependencies and impacts.

- Assess

-

- Assess the short-, medium- and long-term risks based on the dependency and impact situation.

- Confirm the current risk management situation and then consider the additional necessary measures against risks.

- Prepare

-

- Input the evaluation related to the important nature-related risks and opportunities to managers. Consider strategies, resource allocation and target setting.

- Disclose in accordance with the TNFD recommendations.

Overview of the LEAP Approach

Organized by ITOCHU based on the Guidance on the identification and assessment of nature-related issues: The LEAP approach![]()

We analyzed on mining process with an especially high impact score in our Metal & Mineral Resources business which we determined has the highest impact on natural capital in our scoping using ENCORE.

First, we identified ecologically sensitive locations in the Locate analysis. We identified these sites using the five definitions for sensitive locations in the TNFD LEAP approach guidance and the indicators in the databases which organize the criteria for those definitions*2. We also identified relevant biome and ecosystem information using the IUCN Global Ecosystem Typology and the Global Map of Ecoregions for some of our business sites after taking into consideration the importance of this business and we performed the Evaluate analysis for the dependency and impact on natural capital. We refined the dependency and impact measurement results in this analysis by investigating the TNFD sector guidance for metals and mining and local environmental assessment reports. As a result, it was confirmed that the mining process of the project has a significant degree of impact on natural capital, as suggested in the scoping.

Subsequently, together with the sales representatives for the metal resource business, we conducted a sampling survey to verify the status of measures related to past environmental assessments and permits for each project. Throughout these dialogues, we could confirm that recognizing the degree of impact of our Metal & Mineral Resources business activities on natural capital we have implemented the projects with stricter environmental assessments and a mine closure policy to reduce future impacts.

Refer to: Policy on Decommissioning of Mining Operations

- The LEAP approach is a method developed by the TNFD to clarify nature-related issues in applicable businesses. This method consists of four steps: Locate, Evaluate, Assess and Prepare

- Databases used: WWF Biodiversity Risk Filter, WWF Water Risk Filter, STAR, Biodiversity Intactness Index, Ecoregion Intactness Index, Critical Natural Asset layers and IBAT

Natural Rubber Business

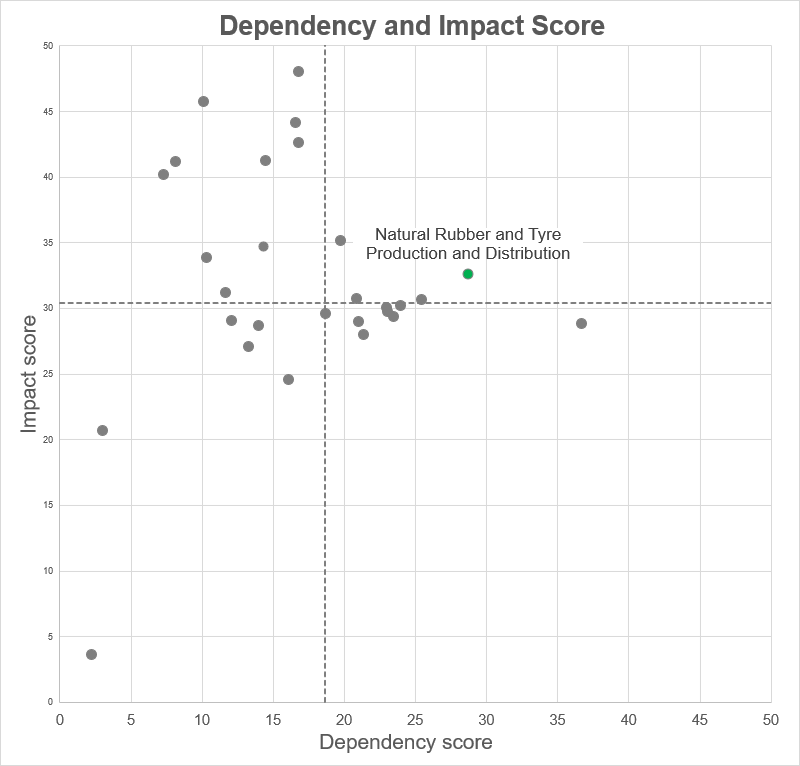

ITOCHU have confirmed the applicability of the LEAP approach to our business analysis through the analysis of our Metal & Mineral Resources business. Subsequently, we conducted a LEAP analysis for our natural rubber business, which has a relatively high dependence on natural capital among our businesses. Natural rubber is also included in the High Impact Commodity List compiled by the Science Based Targets Network (SBTN)*, identifying commodities with a significant impact on natural capital. In general, the cultivation of natural rubber is associated with serious social issues, such as human rights and poverty issues for smallholders. Considering these factors, we determined that conducting LEAP analysis on the natural rubber business would be highly significant to deepen understanding of its dependence and impact on natural capital, and to reduce risks and create opportunities.

- Global initiative to develop science-based targets for nature

The results of our assessment of the dependence and impact of the natural rubber business on each of the business processes indicate that the procurement (natural rubber cultivation) and manufacturing (rubber processing) processes are particularly dependent on the natural capital. Therefore, in this analysis, we focused on these two processes.

- The dashed lines show the average dependency and impact scores of all ENCORE processes

Locate

The natural rubber handled by ITOCHU is mainly produced in Indonesia. We identified sites associated with ecologically sensitive locations using database in the table below, covering all rural villages in the country of procurement and the processing plant of PT. Aneka Bumi Pratama (ABP), a subsidiary of ITOCHU. ABP is a natural rubber processing company.

| Criteria for Sensitive Locations | Database used |

| 1. Importance for Biodiversity |

|

| 2. High Ecosystem Integrity |

|

| 3. Rapid Decline in Ecosystem Integrity |

|

| 4. High Physical Water Risks |

|

| 5. Importance for Ecosystem Service Provision, Including Benefits to Indigenous Peoples, Local Communities and Stakeholders |

|

We rated all rural villages and processing plants on a five-point scale using indicators from each database. As a result, approximately 89% of the rural villages fell into the “2. High Ecosystem Integrity,” and approximately 85% of the rural villages, based on a procurement weight, were included in this category. We also found that many factory sites located near rural villages are also close to protected areas and fall into the category of sensitive location as “1. Importance for Biodiversity.” Areas important for biodiversity are regions of high conservation value that may also contain significant opportunities to protect environmental assets and maintain ecosystem services. We are working to protect the ecosystems and biodiversity of natural rubber production sites through PROJECT TREE, an initiative to prevent uncontrolled growth of farm land, over-cultivation and illegal logging near protected areas.

Evaluate

We evaluated dependencies and impacts on natural capital by natural rubber cultivation and rubber processing processes through literature reviews.

We used the “Environmental Risk Assessment of Natural Rubber Production and Processing” published by GPSNR (Global Platform for Sustainable Natural Rubber).

The review found that the cultivation process of natural rubber is highly dependent on biomass provisioning, genetic material, climate regulation, soil quality regulation, and purification and disaster mitigation services. Also, land use change and solid waste emissions have significant impacts on nature.

In addition, the processing process of natural rubber is highly dependent on water sources (rivers), and water consumption and pollution of soil are found to have significant impacts on nature. Furthermore, based on these literature reviews, our employee, who has several years of expat experience in the field, conducted a close examination of those dependencies and impacts in our operations from the practical perspective.

Assess

Based on the findings of the general dependencies and impacts of natural rubber cultivation and processing processes identified in Evaluate phase, we examined the nature-related risks and opportunities for our business. Specifically, using the LEAP approach guidance and Additional Sector Guidance – Food and Agriculture by TNFD, we developed a comprehensive list of risks and opportunities for natural rubber business and refined the content to reflect the actual situation, in the same way as in the Evaluate phase.

Furthermore, we have evaluated the significance of risks and opportunities on a three-point scale (low, medium, and high), assuming a future scenario as of 2030.

The TNFD developed four scenarios based on two critical uncertainties: “Ecosystem Service Degradation (physical risk)” and “Alignment of Market and Non-Market Forces (transition risk).” We determined that we are in a “#2 Go Fast or Go Home” (a scenario in which the damage from loss of nature is significant, and the public attention for nature is high and cooperative) and assessed the magnitude and likelihood of these risks and opportunities.

The desktop analysis conducted in Evaluate phase indicated that, for example, soil pollution has a significant impact on nature. However, the results of Assess phase showed that the factory we operate has appropriate wastewater treatment and other measures in place, and that the risk is not significant.

#1 Ahead of the Game

- Positive progress on carbon and climate accelerates the turn toward a policy and macro-prudential environment for nature-positive outcomes.

- But actual experienced loss from nature degradation is low.

- There are opportunities for organisations to lead, but also increasing scepticism of overreach on nature, given the lack of proof points about impact and risk, and the lack of visible opportunities in carbon neutral growth.

#2 Go Fast or Go Home

- In a nature-crisis environment where immediate and material business risks are broadly experienced, there will be threshold impacts that bolster the push for faster and more systematic action.

- Public attention and policy focus shifts toward nature as the master problem that subsumes carbon and climate.

- Macroeconomic disruption further compresses the time frame for action on nature, and investment in technologies for nature-positive outcomes skyrockets.

#3 Sand in the Gears

- Environmental assets are deteriorating fast, but politics and finance are too noisy, slow and bogged down in complexity to drive broad and systematic action.

- Organisations are incentivised to stopgap their most severe and acute business disruptions, and externalise the costs and negative consequences where possible. There are perverse incentives to overuse environmental assets in the short term.

- The developed–developing economy divide on benefits from environmental assets widens.

#4 Back of the List

- Nature falls down the list of priorities. Meaningful progress on carbon reduction becomes an even stronger magnet for finance, tech and corporate action because it seems relatively tractable, and a moderately effective – if indirect – way to make progress on nature issues.

- Organisations turn towards a strategy of reducing short-term harm to environmental assets and pull away from long-term planning as there seems to be no way of winning.

Organized by ITOCHU based on the Guidance on scenario analysis

Finally, we organized and discussed measures to address the risks and opportunities that were rated as highly significant.

In the desktop analysis, flooding and other natural disasters were identified as risks related to the natural rubber business. However, since we operate in locations where the occurrence of water-related disasters is low, we recognize that the risk is relatively low. We have also confirmed that measures to address other risks and opportunities have already been taken. Additionally, we also work to realize opportunities by launching a sustainable natural rubber production project called PROJECT TREE starting in 2019. Details on how each risk and opportunity is addressed are provided in the tables below.

| Type | Business Process | Description | Status of Response | Importance | |

| Physical Risks | Acute Risks | Procurement | Decrease in natural rubber yield due to the spread of pathogens and viruses, resulting from the vulnerability to diseases of rubber farm formed by clone individuals. | Conduct educational activities on the importance of proper farm management to prevent the spread of pathogens and viruses in PROJECT TREE. | Medium |

| Decrease in yield and quality due to reduced microbial diversity in the soil and spread of white root rot disease, resulting from the continued monoculture of Para rubber tree. | Recommendation for farmers to grow diverse crops, including agroforestry to prevent white root rot disease in PROJECT TREE. | Medium | |||

| Loss of continuity in natural rubber cultivation due to the increase in natural disasters such as heavy rainfall, floods, and typhoons. | Distribution of purchasing areas in factory suburbs and throughout southern Sumatra. | Medium | |||

| Poor growth and lower yields of rubber trees resulting from deviation from optimal growing temperatures, lack of sunlight, changes in rainfall patterns caused by climate change. | Conduct educational activities on proper farm management in PROJECT TREE. | Medium | |||

| Processing | Damage to factory infrastructure and factory shutdowns due to extreme weather and natural disasters caused by climate change. | Confirmed prompt response capability to natural disasters such as flooding during past events. | Medium | ||

| Inability to appropriately intake water during flooding. | |||||

| Pollution of rivers and watershed soil due to discharge of wastewater exceeding water quality standards into rivers. | Equipped with wastewater treatment facilities and conducts hourly water quality inspection. | Medium | |||

| Chronic Risks | Procurement | Decrease in natural rubber yield and quality resulting from degradation of surrounding water and soil quality due to excessive use of chemical fertilizers by the rubber plantation, and industrial activities in the area. | Conduct educational activities on chemicals that cause pollution and wastewater treatment in PROJECT TREE. | Medium | |

| Decrease in natural rubber yields due to increased pathogens, pests, and vermin. | Conduct educational activities on proper farm management in PROJECT TREE. | Medium | |||

| Transition Risks | Policy/ Laws and Regulation |

Procurement | Introduction and tightening of regulations on sustainability and traceability. | Further expansion of PROJECT TREE that is an activity to ensure traceability and increase the sustainability of natural rubber, promotion of TREE+* implementation | High |

| Introduction or modification of laws and regulations along with strengthening of reporting obligations, to protect the environment around rubber farm. | Through PROJECT TREE, promote regulatory compliance by informing and educating smallholders about laws and regulations. | Medium | |||

| Processing | Introduction or modification of laws and regulations, along with the strengthening of reporting obligations, to protect against the negative environmental impacts caused by rubber processing plants. | Developing environment-related data and improving it as needed. | Medium | ||

| Market | Procurement | Changing customer preferences, including increased demand for products produced and manufactured in sustainable methods with lower impacts on nature. | Spreading sustainable natural rubber production methods to smallholders and supplying the product to the market through PROJECT TREE. | Medium | |

| Decrease in procurement sources as rubber farmers shift crops due to changes in profitability. | Adequate compensation to farmers by PROJECT TREE prevents rubber farmers from crop shifting (redistributing a portion of the sales, etc.) | Medium | |||

| Processing | Transition to nature-positive production methods, including the establishment of manufacturing processes with less environmental impact and the introduction of equipment to improve resource efficiency. | Already using biomass as a heat source for natural rubber drying, considering transition to nature-positive production methods in every situation. | Medium | ||

| Technology | Procurement | Delay in promotion of traceability assurance due to stagnation in smartphone penetration among rubber farmers. | Planning to provide free smartphones to farmers. | Medium | |

| Reputation | Procurement | Increased criticism from consumers and investors and decrease in brand value due to procurement of natural rubber from rural farm with inadequate nature management practices. | Risk assessment of farmers in PROJECT TREE to identify and improve farms with inadequate natural management. | Medium | |

| Criticism of greenwashing due to unsustainable projects claiming to be sustainable. | PROJECT TREE is promoted with the cooperation and guidance of international NGOs, namely, Proforest and SNV. | Medium | |||

| Processing | Cancellation of certification or damage to corporate value due to poor environmental management or resulting from environmental accidents. | In addition to ISO audits by an external organization, PT. Aneka Bumi Pratama (ABP), a natural rubber processing company, conducts annual internal audits to reduce the risk of certification revocation. | Medium | ||

| Liability | Procurement | Lawsuits and fines from local communities due to odors and water pollution caused by waste and pollutants discharged from upstream suppliers. | Conduct educational activities on sewage and waste treatment for farmers in PROJECT TREE. | Medium | |

| Processing | Lawsuits and fines from surrounding communities due to health hazards derived from toxic pollutants by the plant and endocrine disruptors. | Properly dispose of sewage, exhaust, and waste in accordance with rules, laws and regulations. | Medium | ||

- Natural rubber that ensures traceability and complies with the EUDR (EU Deforestation Regulation)

| Type | Business Process | Description | Status of Response | Importance | |

| Business Performance | Resource Efficiency | Procurement | High efficiency of natural rubber supply by PROJECT TREE. | In PROJECT TREE, deploying agricultural technology support and educational activities that contribute to increased yields of natural rubber. | High |

| Breeding (resistance to natural disasters, disease and high temperatures as well as sterilization, etc.) | In PROJECT TREE, major suppliers of ABP are planning to distribute improved varieties developed on their own farm to smallholders. | High | |||

| Promote traceability using blockchain and other technologies. | Collecting data using a traceability system based on blockchain technology developed in-house. Considering the use of data to improve logistics efficiency and reduce CO2 emissions. | High | |||

| Processing | Improved efficiency of waste tires collection process and reconditioning. | Considering the collection of waste tires and the sale of them to used tire shops, utilizing the tire distribution network for Nalnet Communications, a company in which ITOCHU has capital participation. | High | ||

| Products and Services | Procurement | Increased supply of sustainability-certified natural rubber. | Focusing on the supply of EUDR compliant products through PROJECT TREE. Responding to strong demand from tire manufacturers for EUDR compliant products. | High | |

| Processing | Increased supply of recycled products through the waste tires collection. | Of the collected waste tires, those still usable are planned to be resold to consumers via used tire shops. | High | ||

| Market | Procurement | Maintain brand value and market leadership by supplying sustainable natural rubber | Increased incentive income for smallholders from increased distribution of natural rubber certified as origin by PROJECT TREE due to the enhanced brand value of PROJECT TREE. | High | |

| Develop business strategies aligned with Kunming-Montreal Global Biodiversity Framework (GBF) 2030 and 2050 goals. | PROJECT TREE aims to “halt agricultural land development and illegal logging around protected areas,” and can promote GBF “Target 1: Plan and Manage all Areas To Reduce Biodiversity Loss.” | High | |||

| Capital Flow and Financing | Procurement | Access to nature-related and environmentally-conscious funds, bonds, or loans. | Expecting financial institutions to offer and increase the overall financing capacity, such as proposing sustainability-linked loans for companies participating in PROJECT TREE. | High | |

| Sustainability Performance | Sustainable Use of Natural Resources | Procurement | Transition to processes that increase positive impacts and reduce negative impacts on nature. | PROJECT TREE contributes to being nature-positive by avoiding illegal logging in protected forests and is constantly considering a transition to nature-positive production methods. | High |

| Processing | Transition to processes that increase positive impacts and reduce negative impacts on nature through the establishment of recycling systems. | Aiming to reduce environmental impact by reusing tires that were previously discarded. | High | ||

Note that this section focused on those rated “medium” and “high” for risks, in order to ensure proper identification and mitigation of risks, and those rated “high” for opportunities.

Prepare

In order to mitigate significant risks and create opportunities, it is important to ensure traceability and reduce environmental impacts in collaboration with farmers. The core global indicators that TNFD recommends for disclosure and our specific collection indicators that we have considered based on the results of our analysis are as follows.

| Metric No. | Category/Indicator | Collection Metrics | (Reference) Related Risks and Opportunities |

| C3.1 | Quantity of high-risk natural commodities sourced from land/ ocean/freshwater |

|

|

| C1.1 FA.C1.0 |

Land/freshwater/ ocean-use change (regenerative and sustainable land management) Deforestation-free Products |

|

|

| A22.0, A22.1, A22.2, A22.3, A22.4 | Value Chain |

|

|

| Company-specific | Physical Risks |

|

|

| Company-specific | Transition Risks |

|

|

In addition, we collect other metrics on water consumption, CO2 emissions, etc. We also intend to consider setting measurable targets.

PROJECT TREE

To sustainably procure natural rubber, it is important to reduce negative impacts on both the environment and human rights. To this end, it is important to ensure that natural rubber is not produced in protected areas and that child labor is not employed in its production. However, since most natural rubber cultivation is carried out by smallholders, ensuring traceability is challenging. We have established the Natural Rubber Procurement Policy![]() , and join the Global Platform for Sustainable Natural Rubber (GPSNR), a new global platform for sustainable natural rubber, as the only Japanese trading company founding member.

, and join the Global Platform for Sustainable Natural Rubber (GPSNR), a new global platform for sustainable natural rubber, as the only Japanese trading company founding member.

In addition, we are focusing on PROJECT TREE, which utilizes a supply chain management system uniquely developed for our natural rubber business. This initiative leverages a traceability system we developed based on blockchain technology. Through a smartphone application, the location of each farmer's farm, transaction details of natural rubber, date and time, and location information are recorded on the blockchain and can be checked on a map. Raw materials delivered from smallholders via collectors and dealers are processed by ABP, our subsidiary, and sold to tire manufacturers as natural rubber materials with origin information. A portion of the sales from tires sponsored by PROJECT TREE is paid as a premium to the smallholders who supply raw materials, thereby contributing to improve their living standards. Furthermore, to increase the volume of natural rubber handled in this project, we are working to expand the number of participating farmers and further enhance traceability by distributing smartphones to smallholders free of charge. Additionally, as part of the project, we conduct educational activities on proper farm management and wastewater treatment, collaborating with farmers to promote sustainable agriculture.

Refer to: PROJECT TREE![]()

Initiatives for Businesses with a High Dependency

ITOCHU’s businesses with a high dependency on natural capital are the procurement, manufacturing, processing and distribution of forest commodities (food, timber, natural rubber, palm oil, etc.). We have established procurement policies for each product to improve the sustainability of these businesses. We strive to procure products certified by international third-parties which allow us to identify the procurement area through traceability.

Refer to: Procurement Policies by Product Type

We categorize and organize initiatives in businesses with a high dependency on natural capital into four: avoid, reduce, restore/regenerate and transform. We perform this categorization using the framework of the Mitigation Hierarchy* in the AR3T Action Framework published by the Science Based Targets Network (SBTN) in the Science-Based Targets (SBTs) for Nature.

- Avoid

- Prevent negative impacts from happening in the first place; eliminate negative impacts entirely

Example: Adopt sustainable alternative raw materials and packaging materials

- Reduce

- Minimise negative impacts that cannot be fully eliminated;

Example: Reduce waste and pollutant emissions

- Restore

- Initiate or accelerate the recovery of an ecosystem with respect to its health, integrity and sustainability, with a focus on permanent changes in state;

Example: Improve the soil or plant trees in land modified during business activities

- Regenerate

- Take actions designed within existing land/ocean/freshwater uses to increase the biophysical function and/or ecological productivity of an ecosystem or its components, often with a focus on a few specific ecosystem services.

Example: Protect endangered species

- Transform

- Transformative action, which covers the ways organizations can contribute to needed systemic change inside and outside their value chains.

Example: Develop sales and manufacturing models and participate in initiatives

Overview of the Mitigation Hierarchy

Organized by ITOCHU based on the Science Based Targets Network website![]() and TNFD Recommendations

and TNFD Recommendations![]()

- This is a tool to reduce the negative impacts from business on natural capital. It indicates the approach to predict and avoid or minimize risks to biodiversity (loss of wildlife habitats etc.) and impacts on local communities (release of pollutants which may impact health). It also shows the approach to recover as far as possible from any negative impacts which do occur

As a result of the above analysis, we have found that we are actively taking actions relating to “avoid” and “reduce” which should be given top priority under the SBTs for Nature to reduce nature-related risks. We will continue to further promote AR3T actions in the future to realize nature positivity.

| Major Category | Commodity | Specific Initiatives | |

| Forest resources | Timber | Avoid | Achieving a handling ratio of certified or highly controlled materials of 100% |

| Transform | Engaging with NPOs | ||

| Natural rubber | Transform | Participating in the Global Platform for Sustainable Natural Rubber (GPSNR) as a founding member and cooperating in formulating and operating platform standards | |

| Palm oil | Avoid | Achieving 100% traceability at the mill level | |

| Transform | Joined the Roundtable on Sustainable Palm Oil (RSPO) and promoting initiatives | ||

| Biomass fuel | Avoid | Procuring legally accepted woody biomass fuel according to the Programme for the Endorsement of Forest Certification (PEFC), the Forest Stewardship Council (FSC) and other third-party certification | |

| Food | Cocoa beans and coffee beans | Avoid | Enhancing traceability of cocoa beans |

| Avoid | Enhance the handling of sustainable certified coffee beans | ||

| Transform | Providing technical support to small farmers such as by giving them agricultural technology to improve productivity | ||

| Dairy products | Reduce | Reducing ecological degradation by raising dairy cows while changing their grazing land regularly in New Zealand | |

| Meat | Avoid | Built a system to enable 100% trace back to the production stage for all meat suppliers | |

| Marine products | Avoid | Acquired distributor certification from the Marine Stewardship Council (MSC) and Chain of Custody Certificate (CoC) | |

| Transform | Encouraging fishermen about skipjack and yellowfin for which MSC certification is limited | ||

| Fruits and vegetables | Reduce | Using clean energy in our Dole business | |

| Textile raw materials | Cotton | Avoid | Acquired Global Organic Textile Standard (GOTS) certification and achieving 100% traceability for our procurement of organic cotton in India |

| Environmentally-friendly materials | Reduce | Launched the RENU® project with the aim of realizing a circular economy and started to develop recycled polyester | |

| Apparel | Outdoor apparel | Restore/ Regenerate |

Planning and selling charity goods and then using some of the proceeds in the funds to purchase land for tropical rainforest restoration and the protection of Borneo elephants |

Initiatives in Business-related Areas

ITOCHU is working with stakeholders to protect endangered wildlife.

- Mangrove Planting Project with Uken Village of Amami Oshima Island

- Collaborative Conservation Project for Rare Freshwater Fish with Shiga Prefecture and Shiga Prefectural Lake Biwa Museum

- Hunting World’s Wildlife Conservation Activities

- Support of Amazon Ecosystem Conservation Program

- Project for Protecting Green Turtles, an Endangered Species

- Activities to Restore the Tropical Rainforests and Conserve Borneo’s Ecosystem

Metrics and Targets

ITOCHU conducts product certification and traceability for biodiversity conservation in products handled in businesses including the supply chain, and social contribution activities for biodiversity conservation in business-related areas. We consider forest resources (wood, wood products, paper raw materials and paper products, natural rubber, palm oil), dairy products, meat, marine products, and textile raw materials as important commodities for biodiversity and strive to disclose information and set goals for them.

Targets in Business Activities

Please scroll sideways.

Please scroll sideways.

- Sustainable palm oil: palm oil supplied from supply chains compliant to RSPO and RSPO-equivalent standards

- NDPE (No Deforestation, No Peat, No Exploitation): zero deforestation, zero peatland development, zero exploitations

- MSC (The Marine Stewardship Council): an international NPO established in 1997 to work on spreading sustainable fishing. It is headquartered in London, England

- CoC (Chain of Custody Certificate): A certification for processors and distributors to ensure the traceability of MSC certified marine products and other products in the management of processing and distribution processes specified by MSC

Refer to: Procurement Policies by Product Type

Targets in Business-related Areas

Performance Data

Performance Data in Business Activities

- Performance Data Regarding Forest Certification and Legal Compliance, Sustainable Procurement Performance Data of Raw Materials for Papermaking

- Performance Data on Natural Rubber

- Performance Data Regarding Sustainable Palm Oil Procurement

- Performance Data on Sustainable Coffee Bean Procurement

- Performance Data on Traceability of Meat

- Performance Data Related to Certification of Marine Products

- Performance Data on Organic Cotton Procurement

Performance Data on Business-related Areas

Action Plan

Please scroll sideways.

Please scroll sideways.

| Materiality | SDGs Targets | Impact Classification | Issues to Address | Business Area | Commitment | Specific Approach | Performance Indicators | Degree of Progress |

| Textile Company | ||||||||

| Ensure Stable Procurement and Supply |  |

Prevention of Pollution and Circulating Society | Reducing our environmental burden by circulating society | Textile products in general | We will contribute to realize a Circulating Society through our sustainable textile products and recycling of them. | Promote sustainable products and projects leading to the recycling of resources. | Promote the sustainable products such as “RENU”, a recycled polyester derived from textile, and set up schemes to recycle textile products. |

|

| Metals & Minerals Company | ||||||||

|

|

|

Sustainable mine development that pays continuous careful attention to the risks in occupational safety and health and environmental risks, and that contributes to local communities’ well-being | Mining business |

|

|

|

|

| Food Company | ||||||||

| Address Climate Change (Contribute to a Decarbonized Society) |   |

GHG Emissions | Taking countermeasures against climate change | Fresh food field | We will examine and promote measures that contribute to tackling climate change. | Dole will utilize green energy in our processed food business. |

|

Result in FYE 2025

|

|

|

Supply Chain | Establishing a supply chain reflecting consideration for human rights and the environment | Provisions field | We will develop a procurement structure compliant with third-party body certification and supplier-specific codes of conduct. |

|

2030

|

Support Achievements to Each Producing Country (Qualitative)

|

|

|

Supply Chain | Responsible Fisheries Procurement | Fresh food field | We will develop a procurement structure compliant with third-party body certification and supplier-specific codes of conduct. | Promote procurement in accordance with the supplier’s own code of conduct in the country of origin of the tuna. | Develop a tuna procurement policy and promote procurement of products and certified products that comply with the policy. |

|

| General Products & Realty Company | ||||||||

|

|

Forest | Using sustainable forest resources |

|

We deal in sustainable forest resources to reduce the impact on the environment and prevent the increase of greenhouse gases. | We handle certified or high-level management confirmed materials. | Ensure a 100% handling ratio of certified or high-level management confirmed materials. | In FYE 2025, 100% of our Pulp, Woodchips and Wood Products & Materials transactions were handled as certified material or were intensively managed. |

|

|

|

Realization of sustainable supply of natural rubber | Natural Rubber |

|

|

|

|

Collaboration with Outside Initiatives

Initiative Participation (Activities Through Business and Industry Groups)

ITOCHU participates in the Japan Business Federation (Keidanren). We support nature conservation projects in developing areas mainly in the Asia-Pacific region and in Japan through the Keidanren Committee on Nature Conservation that was established in 1992 when the United Nations Conference on Environment and Development (Earth Summit) was held in Rio de Janeiro in Brazil. The Keidanren Committee on Nature Conservation has been working to build an environment in which the business community strives to conserve nature. This has included exchanges with NGOs, the holding of seminars and symposia, and the announcement of the Declaration of Nature Conservation by Keidanren, the Declaration of Biodiversity by Keidanren and the action guidelines for them (revised in October 2018). In addition, we have declared our approval of the Keidanren Initiative for Biodiversity Conservation announced on June 11, 2020. We are also participating in the TNFD Forum, which was established in September 2021, to accelerate discussions in the Taskforce on nature-related Financial Disclosures (TNFD). In October 2024, ITOCHU registered as TNFD Adopters, declaring our intent to disclose information based on TNFD recommendations.

Cooperation with External Organizations

It is especially important for the entire value chain to work together to realize sustainable business activities for businesses with a high dependency on natural capital such as forest commodities (food, timber, natural rubber, palm oil, etc.).

ITOCHU joined in the Roundtable on Sustainable Palm Oil (RSPO) in 2006. We have set a target of handling only RSPO certified palm oil or palm oil equivalent to that by 2030. We are working on the procurement and supply of sustainable palm oil through cooperation and collaboration with other member companies. We are also participating in the Sustainable Palm Oil Transparency Toolkit (SPOTT). This is a project by the Zoological Society of London (ZSL) that assesses major palm oil related companies in terms of more than 50 indicators based on data released to the public. We disclose information to stakeholders relating to the palm oil industry through two-way communication.

In addition, we also joined as a founding member in the GPSNR. We have agreed to the 12 principles stipulated by this platform about natural rubber and comply with the applicable policy components.

Initiatives related to forest commodities are also disclosed in the form of responses to CDP questionnaires, a global corporate disclosure system for companies and organizations.

We have also joined the Organization for the Promotion of Responsible Tuna Fisheries (OPRT) established for the sustainable use of tuna resources in 2012 in our skipjack and yellowfin business. We are promoting initiatives that comply with OPRT’s voluntary management regulations.

Through cooperation with external organizations as described above, we aim to achieve the goals set forth in the “Metrics and Targets” section.

- Roundtable on Sustainable Palm Oil (RSPO)

Refer to: Initiative Participation - Global Platform for Sustainable Natural Rubber (GPSNR)

Refer to: Commitment to the Global Platform for Sustainable Natural Rubber (GPSNR)

- CDP

Refer to: CDP (Climate Change, Water Security and Forests) - Organization for the Promotion of Responsible Tuna Fisheries (OPRT)

Refer to: Sustainable Procurement: Policies and Initiatives by Product Type - International Seafood Sustainability Foundation (ISSF)

Refer to: Sustainable Procurement: Policies and Initiatives by Product Type